COLD Foods Packaging

Trends Driving Reusable Packaging Growth Along the Cold Chain

Adoption of automation

Recently, we’ve seen an increase in the use of automated systems along the cold chain due in part to the lack of available labor in the market. This adoption of automation is also driving companies to implement packaging solutions designed to work well in automated applications.

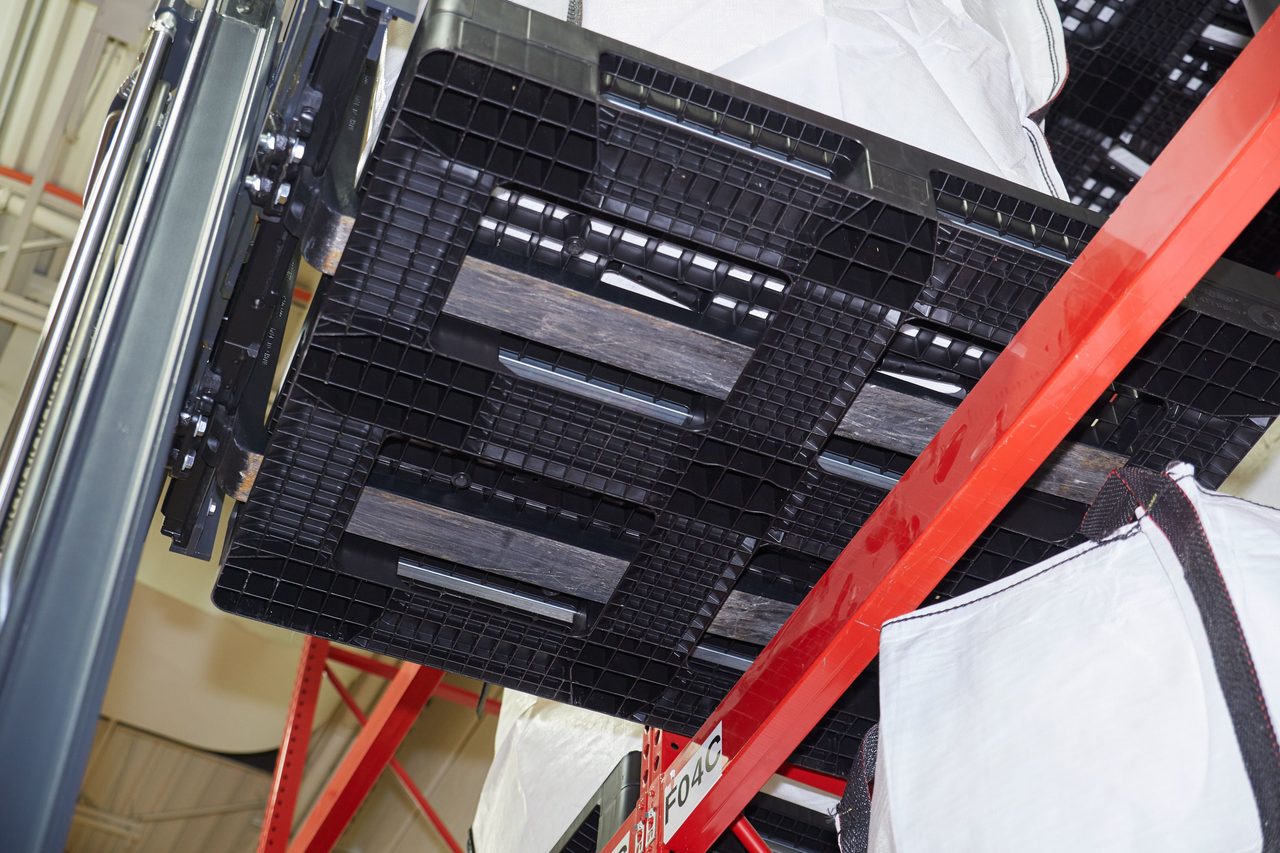

One reusable packaging solution that’s optimized for automation are plastic pallets. Unlike traditional wood pallets, plastic pallets are dimensionally consistent and create a smooth interface between automated systems and product loads. On the flip side, wood pallets have a higher likelihood for broken boards or nails popping out, causing potential downtime in an automated system, as well as possible product damage. Certain reusable plastic pallets also have molded-in frictional elements that can prevent slippage off fork equipment, maximizing product protection and employee safety.

But before implementing automated processes, it’s important to ensure your packaging integrates well into the system as it can be costly and time-consuming to retrofit your packaging after implementation.

From the processing plant to the warehouse and into the brick-and-mortar store or to the curbside for customer pickup, the complexity of the cold chain and its many stops makes packaging an important consideration for food safety. Given the temperature-sensitive nature of dairy, meat, beverages and frozen products, it is imperative that they are efficiently stored and transported along these multiple stops in the supply chain.

In making packaging decisions for the cold chain, companies need solutions that will help them achieve efficiencies in handling across systems while ensuring their product is moved quickly and without damage. Reusable plastic packaging solutions can help ensure cold goods make it to the refrigerator or freezer safely, while delivering the seamless handling experience the cold chain requires. Why adopt reusable packaging? There are four main trends driving the shift toward reusables in packaging for cold supply chains:

In making packaging decisions, companies need solutions that will help them achieve efficiencies in handling across systems while ensuring their product is moved quickly and without damage. All photos courtesy of ORBIS Corporation.

Push for sustainability

In recent years, even pre-COVID-19, supply chain sustainability has increasingly become a top-of-mind issue for companies. This trend has encouraged companies to seriously investigate plastic pallets and other reusable solutions as replacements for their expendable packaging to lessen waste, reduce energy use and cut greenhouse gas emissions. The usage of plastic pallets not only reduces the amount of lumber waste, but also reduces the emissions and water needed to manufacture or recycle wood pallets after their limited use. Unlike wood, the long-term, repeatable performance of reusable plastic packaging solutions leads to less waste, adding to their ROI and sustainable advantages. What’s more, these solutions can then be recycled and reprocessed into new solutions at the end of their useful life with zero impact to the solid waste stream.

Taking it a step further, some companies look to incorporate innovative sustainable materials into their packaging solutions. Depending on the packaging provider, companies can incorporate coastline plastic waste at risk of entering our oceans into solutions for their supply chain. Some reusable packaging companies also offer buy-back programs where they will purchase obsolete packaging that has reached its end of life and repurpose it into new packaging products.

Increased need for hygienics

The events of the past 18 months have elevated the importance of hygienic and sanitary packaging solutions, especially in food plants and warehouses. This means that packaging must be hygienic to keep food products safe for consumption. In turn, packaging needs to have a hygienic design that’s easy to sanitize, able to withstand different temperatures and moistures within the environment, and reduce the risk of product damage.

Hygienic reusable plastic packaging solutions are fit for specific, and sometimes highly regulated, industries and applications. They’re easily sanitized, making it a better fit for cold supply chains than traditional wood solutions. This ease of cleanability is also important as these solutions come into contact with numerous food products before being reused.

The design of reusable solutions also affords minimized areas for contaminants to collect, with no hidden cavities or shallow areas. This same all-plastic construction makes reusable solutions very durable and prevents them from breaking down like corrugated boxes and wood pallets, further contributing to their hygienic and ergonomic benefits.

Retail-ready bulk displays for refrigerated goods like milk or water also support the efficient delivery and merchandise of product as they seamlessly wheel off the truck and right into walk-in coolers.

Boom in e-commerce

The best supply chains deliver products seamlessly from the manufacturer through distribution to the shelf and consumer. With e-commerce and curbside pickup continuing to rise, packaging must also support effective and efficient merchandising. Retailers are looking to reusable packaging solutions that support the quick unload and merchandising of their store, decrease touchpoints and add efficiency.

Mobile to static pallet solutions allow companies to move goods from the truck to the point of sale for a one-touch replenishment operation. This accelerates load and unload times at the retail location and helps grocers quickly fulfill orders to deliver curbside. To quickly and efficiently fill online orders, finding packaging that eliminates the need for bulky material handling equipment in the retail setting is essential.

Some reusable plastic pallets have molded-in frictional elements that can prevent slippage off fork equipment.

For those in the cold chain food industry, keeping food fresh and safe throughout its entire supply chain journey is of the utmost importance. But in today’s cold chain, packaging solutions for the food industry must not only safely store and transport food, but also seamlessly integrate with automated systems, reduce contributions to climate change, keep products safe for consumption, and support e-commerce operations.

Reusable packaging can help you do all this, while maintaining the cold chain’s fundamental mission to efficiently transport food. Work with a reusable packaging manufacturer to determine the best solutions for your operation, and where you might be able to make optimizations.