COLD FOODS PRODUCTION

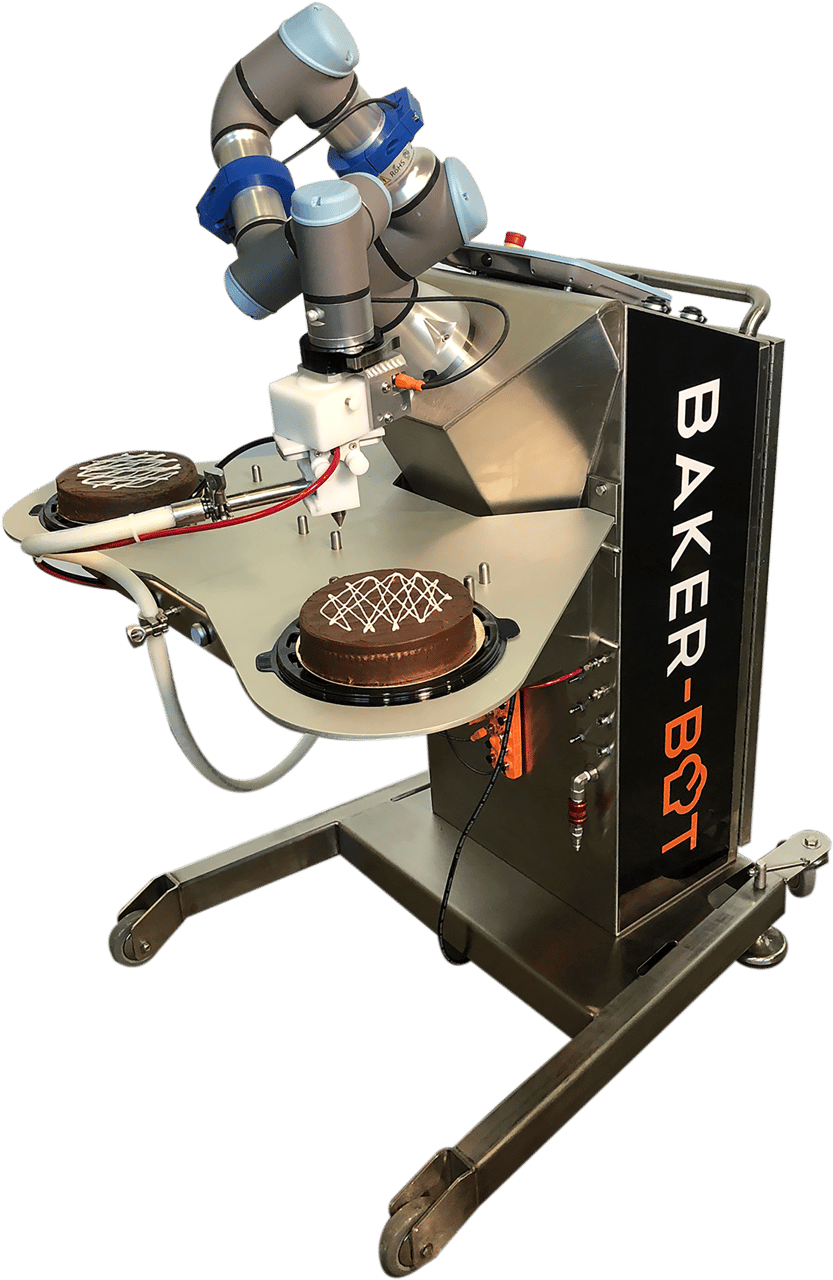

ROBOTIC CAKE DECORATING

Apex Motion Control, specialists in robotics and automation for the baking and food industry, has transformed the cake decorating process with the Dual Baker-Bot decorating line. This provides bakeries with a new way to effortlessly decorate cakes without any strain, thanks to these collaborative robots. With its easy-to-use interface, all you need to do is draw a design onto the Baker-Bot’s tablet, then the Baker-Bot can easily handle the rest. This system can create designs ranging from personalized messages to intricate patterns, resulting in endless possibilities. By combining two of these Baker-Bots together onto the same conveyor line, bakery manufacturers can increase their throughput while still maintaining quality and consistency.

Apex Motion Control

(778) 298-8292

PRECISION SLICING FOR MEAT AND CHEESE

The GEA OptiSlicer 6000 has a higher capacity, better blade design for a smoother cutting action, eye-level electronics and a new clear-view operator panel. The machine is easy to maintain, ultimately reliable and benefits from GEA’s leading remote maintenance service. Regularly shaped products, such as calibrated sausage, salami, cooked ham and cheese, even products that are known to be difficult to slice, can be handled easily without the need for crust freezing. The OptiSlicer 6000 can also be mirrored in left and right-hand versions to minimize footprint and enhance productivity. The OptiSlicer 6000 operates at up to 1500 rpm, with a wide cross section, up to 500 mm width x 200 mm height is capable of handling multiple product logs, of up to 1,850 mm length simultaneously, giving the highest capacity in the sector.

GEA

(844) 432-2329

FROZEN FOOD LUMP BREAKER

The Nibbler lump breaker from process equipment manufacturer Gericke USA enables food, pharmaceutical, nutrition, and other processors to reprocess off-spec products, scrap, and other materials and convert the costly waste into invaluable, saleable product. Set inline to capture material for reprocessing automatically or as a stand-alone unit for manual loading, the Nibbler features a proprietary high-torque, low-speed cutting system that shears chunks, clumps, and blocks through a serrated screen to reduce the particle size down to as small as 1 mm without adding heat history. The rugged lump breaker excels in recycling frozen foods, chocolate, candy bars, biscuits and breakfast cereals, charred or broken snack chips, and other off-spec materials that require a powerful cutting action in a sanitary design that also safeguards particle integrity. Available in seven standard models and in custom models to accommodate any off-spec product or reclaim process, the Nibbler comes in either stainless steel or carbon steel as standard with a choice of screen sizes to meet target particle sizes from 1 mm up to 25 mm.

Gericke USA

(855) 888-0088

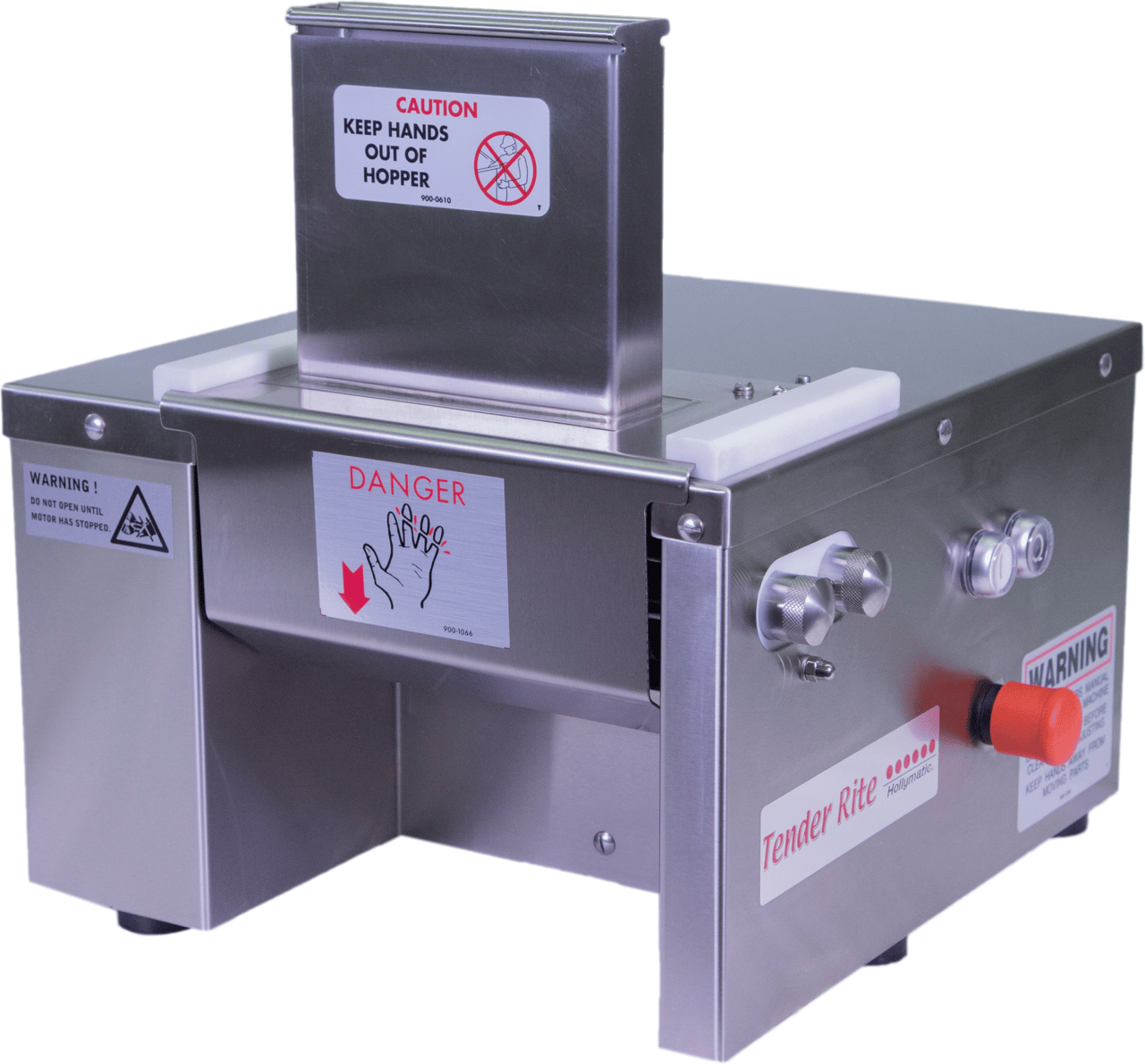

HYGIENIC, VERSATILE TENDERIZER

Hollymatic has combined four sought-after features/benefits and put them all into one tenderizer machine that provides customers with a real profit center. The Tender-Rite Tenderizer offers power, safety, efficiency and a competitive price to add profits to grocery store and supermarket operations as well as small to medium-sized processing plants. A ¾ HP motor has the power to process up to 1200 steaks per hour. The Tender-Rite’s hygienically superior design with all stainless steel housing and inlet improves food safety. Stronger tenderizing blade assemblies provide greater efficiency. With optional stir-fry slicing blades, butchers and processors can create stews and sliced portions. Hollymatic also offers a Deep Cut Tenderizing option with the machine.

Hollymatic

(708) 579-3700

PROCESSING FOR SMOOTH FOODS

SinnovaTek, a developer and integrator of advanced food processing equipment and technology, announces the Nomatic Precision Processing System for smooth food products produced on a small scale. With a throughput range of 1-3 liters per minute (lpm), Nomatic ensures retention of nutrients, quality, color, and flavor. It is ideal for producing baby food, sauces, and fruit and vegetable purees. Featuring a portable design and small footprint, Nomatic is easy to move and can fit through a standard door. The integrated clean-in-place (CIP) system means the system is easy to clean and the user-friendly control panel ensures simple operation and control.

SinnovaTek

(919) 694-0974