A global pioneer in the sustainable food and beverage industry, SunOpta has achieved consistent growth and deep-rooted success for 50 years.

Collaborating with some of the most planet-friendly brands in the world, SunOpta produces nearly 450 product SKUs, many of which are total organic, non-GMO plant-based and specialty products, including plant-based beverages, broths and better-for-you fruit snacks.

Today, the company is focused on sustainably building a plant-based future for leading natural and private label brands, as well as its own brands, including Sown, Dream and West Life.

“Since SunOpta was founded 50 years ago, sustainability has been part of the company’s DNA. As a processor of plant-based foods and beverages, SunOpta collaborates with major brands to help make their production, operations and supply chain more sustainable. We are thrilled that SunOpta's leading sustainability efforts, steadfast growth and innovation across key areas of manufacturing and production are being recognized by Refrigerated & Frozen Foods as the 2023 Processor of the Year,” said Lauren McNamara, vice president of Food & Beverage at SunOpta. “At SunOpta we are committed to sourcing, processing, and producing organic, Non-GMO plant-based, and specialty products and being awarded with this honor is a testament to the incredible work of our entire team across all levels of the company.”

SunOpta’s revenues increased last year by 8.4% to over $221 million, reflecting 10.8% growth in its plant-based segment.

SunOpta has collaborated with some of the most planet-friendly brands, including some of the largest coffeehouse chains in the world. Courtesty SunOpta.

Product Innovation

SunOpta’s research and development (R&D) team has ongoing goals to address consumer health concerns and proactively improve the nutrition profile of its products. Their global headquarters, opened in 2022, includes a pilot plant and an R&D center eight times the size of the company’s previous location.

“The space – known as the Eden Prairie Innovation Center, or EPIC — includes resources for creating new products, experimenting with prototypes, and extensive sampling and benchmarking capabilities. We are using this space to further expand our co-manufacturing, private label, ingredient and branded product offerings across all categories to fuel the future of food,” said Bryan Clark, head of Research & Development at SunOpta.

The company says 99.7% of the ingredients used in U.S. facilities are sourced from Tier 1 supplier facilities certified to a Global Food Safety Initiative (GFSI) recognized food safety certification program. SunOpta facilities maintain certified food safety and quality systems as defined by GFSI and demonstrate the effectiveness of our Safe Quality Food standard via annual external assessments conducted by Mérieux NutriSciences.

As one of the largest producers of private label, co-manufactured, and owned brands in the market, SunOpta produces nearly seven out of 10 of the brands of plant-based milks on shelves today, including oatmilk as a core specialty. The company is betting big on oatmilk, spending $125 million on a new facility in Texas and aiming to double its plant-based business by 2025, with oatmilk at the helm.

Building Better

SunOpta’s environmental achievements include carbon emission savings, recyclable packaging, upcycling food waste, water conservation and zero-waste manufacturing. Zero waste (SunOpta has adopted a zero waste definition as 90% diversion of waste from landfill) has been achieved at six of SunOpta’s operating manufacturing plants.

Overall, SunOpta in 2022 reduced electricity usage in its facilities by 31.7% from its baseline year in 2019.

A new 252,000-square-foot warehouse in Alexandria, Minnesota, brings distribution operations completely in-house, consolidating three sites into one.

“We anticipate a cost savings between $60,000 to $250,000 per year with the new warehouse, along with a significant reduction of at least 5,000 gallons of consumed diesel and over 100,000 pounds of CO2 emissions annually when compared to our current network,” McNamara said. “The warehouse offers an impressive capacity of approximately 20,000 pallet positions and was constructed with the foresight for future expansion, allowing for an additional 75,000 square feet of space.”

27 of SunOpta’s branded products are enrolled in The Non-GMO Project. Courtesy SunOpta.

SunOpta’s corporate HQ in Minnesota has 742 solar panels estimated to produce up to 447,667-kilowatt hours (kWh) on an annual basis, in turn reducing up to 317 metric tons of carbon dioxide (CO2) per year. Courtesy SunOpta.

In 2022, SunOpta opened a new 65,000-squre-foot corporate HQ that includes 13,000 square feet of renewable bamboo flooring, 920 LED light fixtures, 630 plantings, six indoor trees, a living plant wall and six skylights.

“We also have five outdoor garden planters for employees to grow organic produce and four electric vehicle charging stations. Our headquarters also self-produces up to two-thirds of our annual energy needs through recently installed solar panels,” McNamara said.

The $125 million Midlothian, Texas, facility, opened earlier this year and will soon manufacture SunOpta’s entire suite of plant-based milks and creamers, along with tea and other products.

Designed with sustainability in mind, the plant helps to reduce carbon emissions, conserve water and efficiently utilize power. Its regional location helps reduce more than 15 million freight miles annually and saves 59 million pounds of carbon emissions.

“In addition, the facility is equipped with water reuse equipment that can save up to 20 million gallons of water a year, an energy-efficient HVAC system that reduces energy consumption by 45%, LED lights and water heaters that reduce power usage by 95%,” McNamara said. “Our Midlothian facility creates a competitively advantaged ‘diamond shape’ with our plant-based facilities in the U.S. for national distribution.”

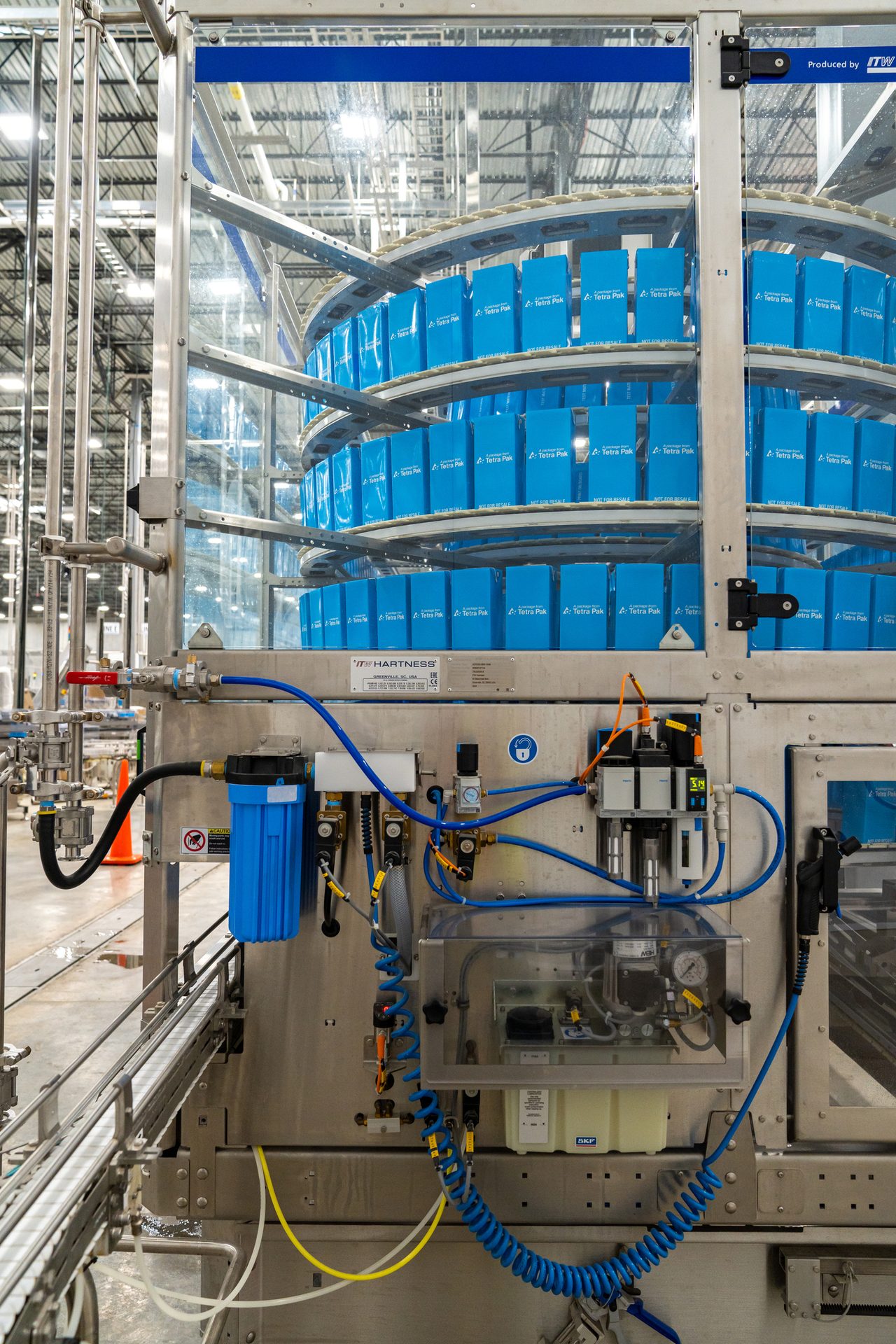

SunOpta produces and packages oatmilk for some of the largest companies in the industry, including the largest coffeehouse chain in the world. Courtesy SunOpta.

SunOpta participates in the U.S. EPA’s SmartWay Transport Partnership, which assesses the efficiency of supply chains and continues to look for packaging efficiencies.

“We recognize the critical role packaging plays in being able to offer safe, nutritional, quality food that tastes good and we are committed to developing innovative packaging solutions,” Clark said. Currently, by weight, of all packaging sourced by SunOpta is 97.3% recyclable. Our packaging engineers have set a goal of having 99% by weight of our own branded packaging to be recyclable, compostable or reusable by 2025.

SunOpta works with Feeding America, donating over 2.3 million pounds of food last year alone.

“As a food and beverage company, we enacted this food waste policy because we recognize the positive impact that we can have on the food system to support food security and nutrition, all the while reducing food loss and food waste,” Clark said.

Much like its company slogan, SunOpta truly is fueling the future of food.