COLD CHAIN OPERATIONS

Performance Based Sprinkler Solutions for Cold Storage

Providing sufficient evidence that the PBD solution either meets or exceeds what exists in the prescriptive standard is a core element in developing alternative solutions. This is typically achieved through computer-based modeling or full-scale live fire testing. Courtesy of kali9 / E+ / Getty Images.

From being harvested, processed or produced, the majority of perishable goods move through freezer or refrigerated warehouses on their way to the local grocery store. These facilities store and process large volumes of commodities on racks that can be 40 feet or higher. Fires in these facilities, while rare, can have financial impacts in the millions of dollars due to damage and disruption to the supply chain.

New analytical tools and processes allows fully optimized fire protection that enables safety and economic upside for storage and refrigerated space. Protecting the loss of the goods and the building in the case of a fire is a critical component in the design and construction of facilities for this industry. To achieve this, dependable and effective fire protection is a necessity.

Sprinkler systems in areas subject to freezing can be challenging to install and maintain due to the harsh operating environments. If a sprinkler were to accidentally operate and discharge water, or even if normally dry sprinkler piping is inadvertently filled with water, clean up and getting the system back in service can be a costly endeavor.

Often, due to the height and the hazard of the commodities present, it is necessary to have sprinklers installed both at the ceiling and within the rack structure itself to provide a sufficient level of control in a fire. In-rack sprinklers are vulnerable to damage from being impacted by forklifts or falling materials. Because of this potential risk, building owners almost always prefer to avoid having sprinklers installed in the racks, but they are fighting against what is permitted in the sprinkler standards and limiting the heights of the storage racks and buildings means a less efficient use of the volume of their building, potentially resulting in lost income.

New analytical tools and processes allow fully-optimized fire protection for frozen and refrigerated food facilities.

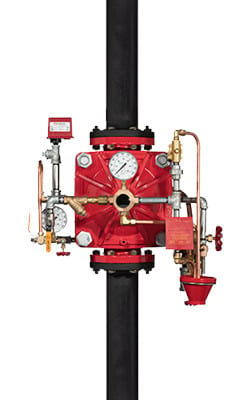

The Quell cold storage fire suppression system uses a PBD approach, for a pre-action sprinkler system that provides a level of protection similar to a wet sprinkler system. Courtesy Johnson Controls.

In freezing environments, dry sprinkler systems are typically employed to prevent freezing of the water inside the pipes installed in the areas subject to freezing temperatures. But, as previously mentioned, in these types of warehouses with high-piled storage and sprinklers installed within the racks, damage to the pipes or sprinklers, or even an unexpected drop in air pressure, can introduce water into the pipes, which may even be discharged from the sprinklers. To combat this, double interlock pre-action systems are often used. These systems prevent water from flowing into the sprinkler pipes unless two separate events verify the presence of a fire.

Typically, this is through detection of heat (with linear heat detection) as well as the activation of a sprinkler head. However, even with double interlock pre-action systems, there is still a risk that the thermal elements of the sprinkler system installed in the racking could be damaged during daily operations.

As an alternative to the available options that can be utilized on a prescriptive bases, designers and engineers can utilize Performance Based Design (PBD) as a viable option to protect these spaces with effective fire protection. Many jurisdictions have processes in place for the use of PBD, and both National Fire Protection Association (NFPA) and the International Building Code include provisions that help guide both the designer and the Authority Having Jurisdiction (AHJ) in understanding this approach.

Providing sufficient evidence that the PBD solution either meets or exceeds what exists in the prescriptive standard is a core element in developing these alternative solutions. This is typically achieved through computer-based modeling or through full-scale live fire testing.

Many fire suppression systems aim to strictly control when water is applied to a fire:

When applied too early, water droplets from the first activated sprinklers can be carried back up to the ceiling by the fire plume and cool the adjacent sprinklers enough to prevent them from activating.

- When applied too late, more sprinklers will activate than ideal for an effective density of water from each sprinkler.

- With full scale fire testing, it is clear that, when the onset of water discharge is kept within the ideal time window, the sprinkler system is able to suppress the fire and contain it to the area of origin.

This design methodology utilizes a means of early detection as one of the pre-action trigger events, typically in the form of linear heat detection. This helps ensure that water is not introduced into the system piping unless the detection system signals heat from a fire along with the operation of a sprinkler. This also allows for preliminary measures to be automatically deployed, such as pre-starting the fire pump to avoid the delay in providing a full flow of water to the sprinklers.

The signal from the linear heat detector will also function to shut down any mechanical ventilation systems. Air flow from these systems can impact where the hot gases from a fire collect at the ceiling and can potentially activate sprinklers that are not directly above the fire. To provide the best level of control, the goal is to open a set number of sprinklers directly over the fire where they can be the most effective at cooling and wetting the at-risk commodities to prevent spread of the fire.

Another key piece of the design method is the use of proprietary large orifice upright CMSA sprinklers that are high-temperature rated to ensure that the heat detector signals the control panel prior to sprinkler activation. The large water droplets that result from these sprinklers are able to penetrate to the base of the fire, where smaller water droplets might be vaporized by the heat of the fire before they are able to reach the fire source.

To properly size the system and accurately predict the delivery time of the water on the fire, a fluid delivery calculation software is used to ensure water delivery to the activated sprinklers is achieved within the required time limit to suppress and contain the fire.

All of the various aspects that make up this specific Performance Based Design are well documented in test reports and data sheets allowing a fire protection engineer to present a solution to an AHJ that is already well supported and peer reviewed. The fire protection industry is always evolving, and manufacturers continue to seek ways to provide a better level of protection for building owners and end-users to protect their assets.

PBD allows for engineering principals to be utilized to develop new ways to protect buildings from challenging fires, but demonstrating equivalency to conservative published standards can be difficult.